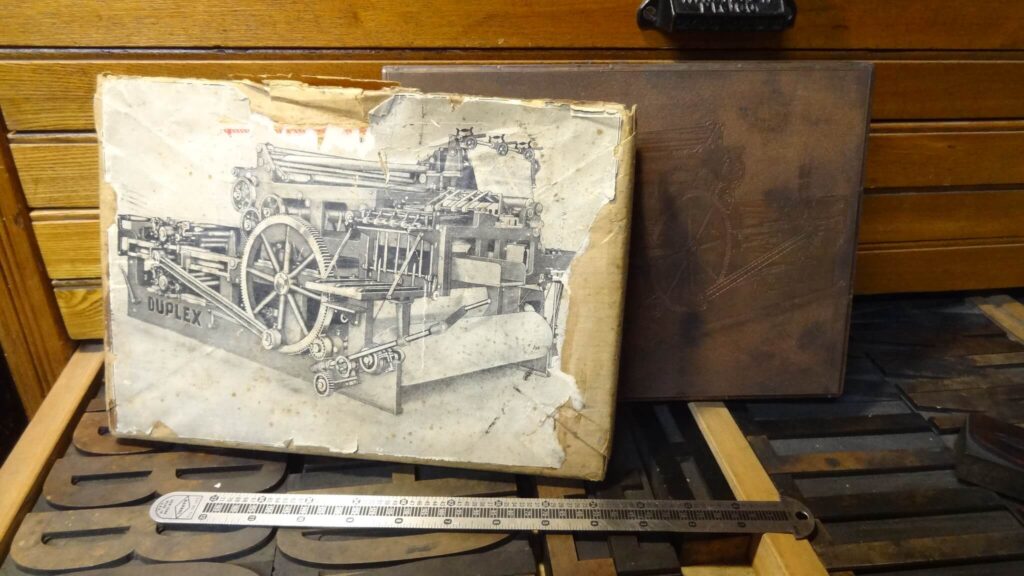

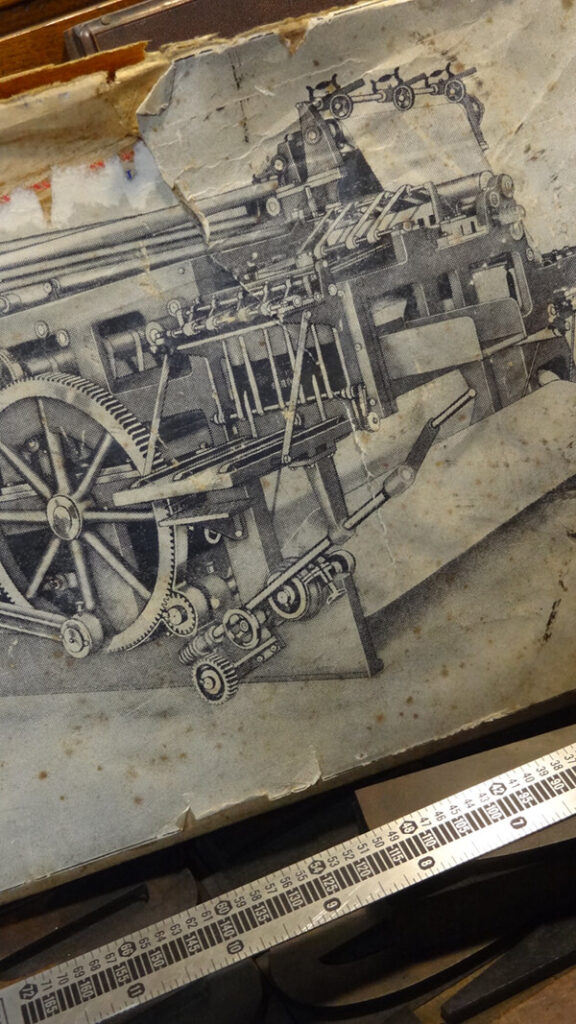

On day at an antique store, I happened on an 11” x 8” copper faced block of a huge printing press. Or was it a printing press? After a little research I found that it was a Duplex reel-fed flatbed perfecting press.

The Duplex’s day-to-day role was somewhere between a cylinder press and a web-perfecting stereotype press used for circulations larger than 10,000. Like the large stereotype presses the Duplex feeds the paper from a roll, prints on both sides of the sheet and delivers a folded paper.

Early presses were designed for general trade. As circulations increased for major newspapers, printing moved from a trade to an industry. Multi-cylinder presses were developed to meet the growing demand for increased pages per hour. Even greater demands lead to the development of type-revolving machines and eventually web-fed rotary presses to meet the need for volume and speed. Not all city newspapers had the circulation to justify huge printing presses and stereotyped printing plates. In 1889, the Duplex Printing Press Company produced a reel-fed flatbed perfecting press to meet the needs of smaller newspapers and general printing. The flatbed design allowed the newspaper lock up type and photos much the same as if they had a cylinder press. Thus, meeting the demand for increased volume without the expense of converting to stereotype production